Ground Transportation

Now that you have purchased a really cool Twin Beech project there is one big question that you have to answer. Just how am I going to get it home? One of the reasons why these Beech's are sitting where they are is because of their size. The wingspan is about 47 feet and the length is about 35 feet. When you take the wings off (they come off just outboard of the engine nacelles) the width is reduced to 17 feet. This can be a pretty wide object to move down the road and maybe even through the gate leading out of the airport. If you live close to the airport this may not be a problem as you might just want to make a bracket or bucket for the tail wheel and tow it by putting the tail wheel in the back of your buddy's pick up truck. A Beech will tow nicely this way but you have to be very careful because the tail wheel is not very strong. If you hit some chuck holes at speed, or try to pull the aircraft out of ruts or on flat tires, you can damage the tail gear or fuselage. Take is slow and easy and have someone follow you with a radio to make sure that you are going to clear objects along your path.

I purchased my first Twin Beech 1982 for $250. Because I couldn't tow my new toy along California highways at 17 feet wide without a Highway Patrol escort, I had to hire a company to move it for me. I found out about an outfit in the LA area that had a rig for moving Beech 18's. I paid $1200 to have it moved only 90 miles. They used a two part welded up frame to tilt it up to 45 degrees. When it is tilted up the width is reduced to 14 feet but it is also 14 feet tall. The rig that they used bolted onto the spar and had a separate cradle for the rear fuselage. The guy said that you had to be careful that if you hit a bump the trailer could twist and this would tweak the fuselage causing wrinkles and damage. I was very worried about this and thought there must be a better way. I was fortunate that the move was successful and the aircraft was delivered undamaged. Moving a Beech at 14 feet wide requires an oversize permit and in most states a pilot car.

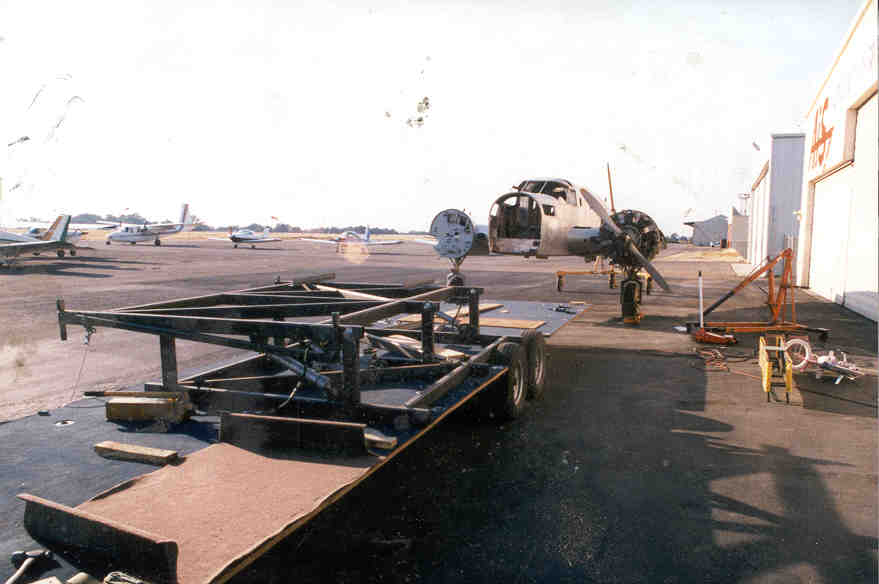

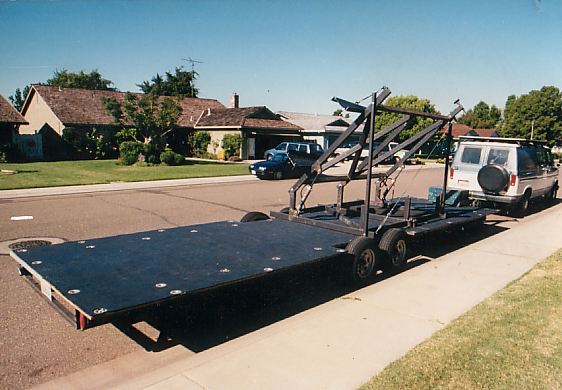

After giving this Twin Beech moving concept a great deal of thought I decided to make my own trailer. I wanted a strong and rigid platform to put the aircraft on to eliminate the flexing/damage issue. I also wanted to be able to back up under the aircraft on its gear so it was easier to load. I wanted to be able to raise the aircraft hydraulically. I also needed a trailer that was set up for the weight of a Beech. Some companies use low boy semi trailers that are made to haul 50 to 100,000 pounds. This suspension is too rigid for a delicate airframe. I built a trailer using two low slung 5000 pound rated axels that work perfectly for the weight of a complete Twin Beech. It was very costly to build this trailer but it was justified as I has purchased three more project aircraft, one in California and two in Arizona. If I had to hire others to move these aircraft it wouldn't have been economically feasible to buy the aircraft.

Moving your new project via this method can be expensive. It can cost up to $6 or more per mile to move a loaded Beech. Unloaded mileage fees are less but this is a major consideration and expense when you are thinking about buying a project.

I have seen plans for home built rigs posted on the internet. So far these plans look to me like they could easily damage an airframe. Please keep these thoughts in mind if you are going to build a rig yourself.

The Beech has a problem with the wing spar cracking. This is due in part to poor welds at the factory and hard landings and ground operations. The Beech spar can be cracked and broken by hard landings and ground loops. The loads imposed on the spar during a ground loop are tremendous. As the aircraft is in the ground loop, the weight of the aircraft and its momentum is placed on the side of the tire and wheel. This side loading is what twists the landing gear in its mounts and may start cracks in the gussets around the slide tube cluster of the lower spar. If you mount your Beech on your trailer up on its side at 45 degrees most of the weight of the aircraft is on the lower attach point. If your lower attach point is the engine mount fittings on the firewall, the wing attach fittings or even the landing gear mounts you are putting too much load on those fittings. Sitting static on the ground is one thing but just think about the loads imposed when you hit a rut or bump going down the highway. It wouldn't take much to transmit the shock and G loads from the road to start cracks in the spar. This can also be accentuated on a stiff semi trailer.

If you use these methods (or have used) to your Beech I would strongly recommend having the spar x-rayed especially on the side of the aircraft that was closest to the ground. I firmly believe that you should support the Twin Beech by the Jack points on the spar between the fuselage and the nacelle. The jack points are just inboard of a scarf joint where the spar telescopes down in size and thickness. This point is extremely strong and can easily support the loads during ground transport. The jack points each have three bosses welded onto the spar to accept 1/4-28 threaded bolts. I use NAS close tolerance bolts but AN4 or grade 8 bolts work as well. Sometimes you will find that the threads inside the bosses have been drilled out. In this case you will need to use longer bolts and nuts on top of the bosses.

The next concern is how to support the rear fuselage. This is where you want to eliminate any movement between your front and rear supports. Any flexing here will "tweak" the fuselage and may wrinkle skins or cause worse damage. I built a platform that is completely rigid to prevent any motion between the front and rear mount points. Since there isn't a good point to bolt to I built a cradle to support the rear fuselage about the bulkheads fore and aft to the entry door. I then used ratchet straps to hold the fuselage down in the carpeted and padded cradle. One big concern is to make certain that the rear fuselage will not sag as it is rotated up. Be sure that the fuselage is held securely so it will put any twisting loads on the front attach points.

Bring along a good pilot car driver (even if one isn't required) to watch out for clearance. From inside the tow vehicle it is hard to see if both sides will clear obstructions, remember you are hauling a big box 14 feet on each side. The pilot car driver can also help when you pass through weigh stations as it doesn't go over well if you smack the eve of the building of the inspection station. I have found that most folks in the weigh stations and police officers will pull you over just to talk about the airplane. I have also run across those who take their job way too seriously, so be certain to have all of your paperwork, permits and regulations in perfect order as if you are expecting a Ramp inspection from the FAA.

All that said, good luck with your move.

Off you go down the road with a load that hardly draws any attention at all! You'll find yourself with your right wheel on the white line or the shoulder most of the time. Construction work, bridges, trees and gawking drivers present the most challenges. That's why it's important to have a good pilot car driver along to help!

Make sure to contact us with any questions regarding this process, whether you're trying it on your own or would like us to handle everything for you. Contact us any time!

Here is the famous aviation auther, Nick Veronico, ready to run even the peskiest gawker out of the way! Try to resist letting your pilot car carry a gun, although the actions of some of the people driving near you warrant a carry permit. As you can see, even the simple things, such as fueling up, can be a challenge.